100,000 Totes: Agility Proves Robots Can Do the Job

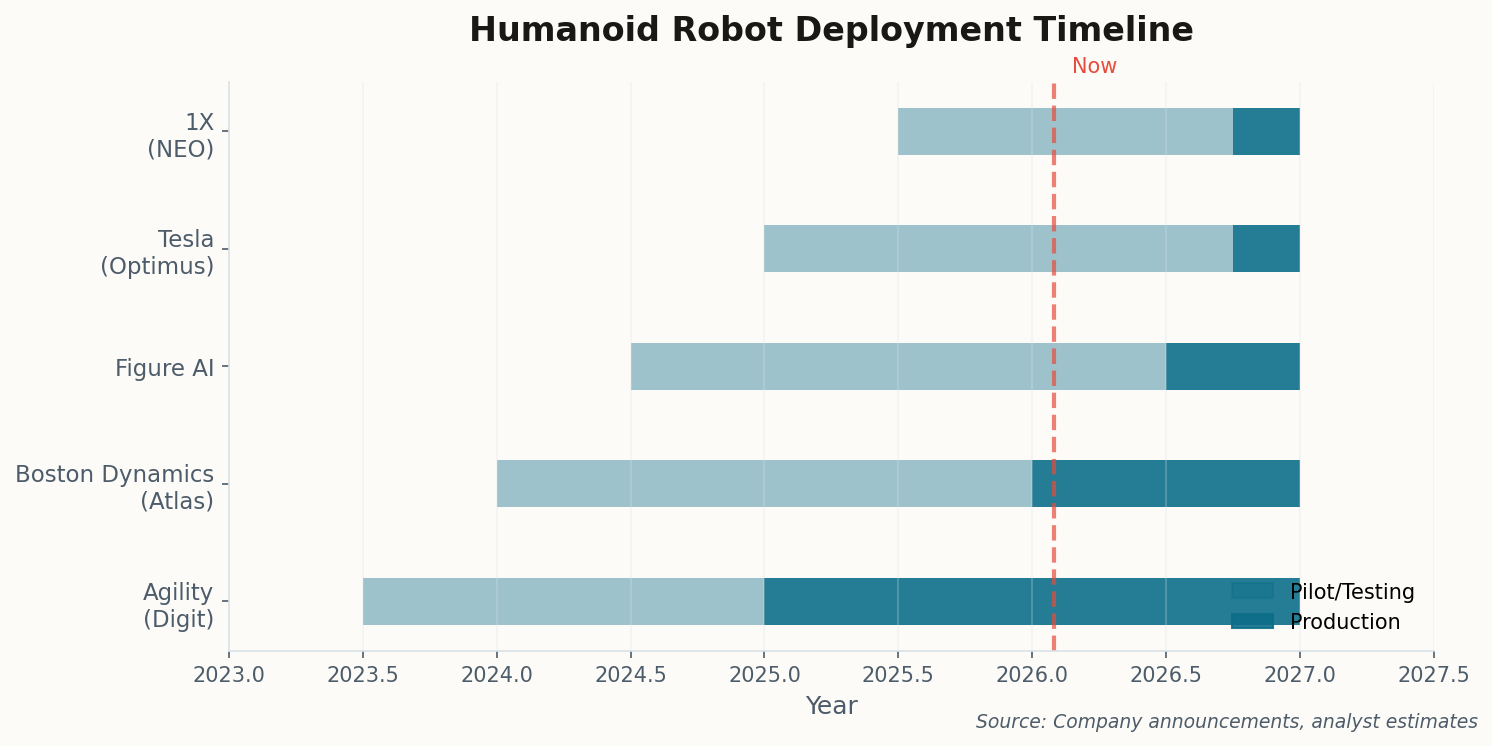

Here's a number that matters more than any demo video: 100,000. That's how many totes Agility Robotics' Digit robots have moved in actual production at a GXO Logistics facility in Georgia. Not in a lab. Not for a trade show. In a real warehouse, doing real work, every day.

While competitors are still unveiling prototypes on conference stages, Agility just announced a new deployment deal with Mercado Libre—Latin America's e-commerce giant—to put Digit robots in fulfillment centers in San Antonio. They're also ramping up production at their "RoboFab" facility from hundreds to thousands of units per year.

The significance isn't the robot's capabilities (though walking, carrying, and sorting are impressive). It's that someone signed a purchase order, deployed it, and kept it running long enough to hit six figures on the tote count. That's the difference between technology and product.